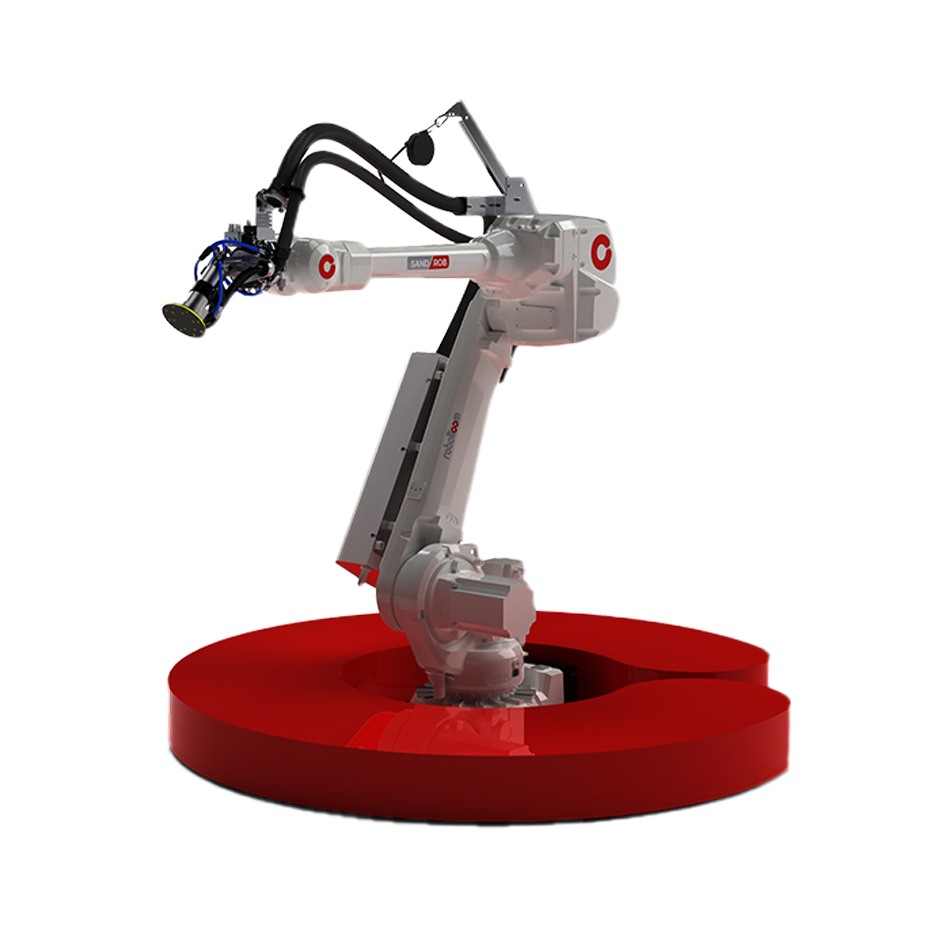

Roboticom SandRob

Automate surface finishing with unrivalled precision.

SandRob by Roboticom is the world’s first 7-axis robotic solution for automated sanding, polishing, trimming, and deburring. Designed to adapt to the most complex shapes and materials — including stone, composites, plastics, wood, and metal — SandRob brings speed, safety and repeatability to every part of your production.

From sculpture to aerospace parts, SandRob makes every finish flawless.

Key Features

- 7-Axis Reach

6-axis robotic arm with an additional rotary table ensures full coverage of even the most complex geometries — with no need for repositioning. - Advanced Force Control

Automatically adjusts pressure during sanding, polishing or trimming for consistently high-quality results. - Multiple End-Effectors

Switch between sanding, polishing, trimming and more — without manual intervention. - Automated Tool Change

Keep production moving with seamless, automated tool switching between processes. - Integrated Dust Extraction

Built-in systems collect dust and debris during finishing or milling, improving safety and surface quality. - User-Friendly Programming

ARPP® offline simulation software lets you plan and program your robotic processes without external tools or code.

Applications

- Sanding & Polishing: Plastics, painted surfaces, stone, wood, metals, ceramics

- Carving & Milling: Sculptures, prototypes, precision components

- Trimming & Drilling: Composites, carbon fibre, solid surfaces

- Deburring & Deflashing: Steel, aluminium, high-performance plastics

Industries Served

- Aerospace

- Automotive

- Art & Sculpture

- Sanitary Ware

- Advanced Manufacturing

- Prototyping & Design Facilities

Technical Data

| Feature | Specification |

| Robotic Platform | 6‑axis anthropomorphic robot + 7th rotary axis (rotary table) |

| Material Compatibility | Metals (aluminum, steel), composites, plastics, solid surfaces, ceramics, wood, painted surfaces |

| Surface Finishing Modes | Sanding, polishing, trimming, drilling, deburring, carving, cutting (incl. waterjet) |

| Force & Speed Control | Active force feedback; electronic speed regulation adjustable via software |

| Tool Handling | Multiple selectable end-effectors; automatic tool and sandpaper change systems with storage racks |

| Dust & Chip Management | Integrated dust extraction via end-effector and harness; optional chip extraction manifold |

| Programming Software | Dry system—no water required, creating a clean and safe workspace |

| Operation Environment | Dry system—no water required, creating a clean and safe workspace |

Why Choose SandRob?

Whether you’re finishing complex aerospace components or sculpting marble, SandRob delivers unmatched flexibility and repeatability across production types. It reduces manual labour, improves safety, and elevates your finishing standards, all while keeping your processes clean, efficient, and consistent.

READY TO FIND THE RIGHT FIT FOR YOUR BUSINESS?

Chat with a member of our experienced team. We’re here to help you find the right machine for your business needs.