CMS Open House: New Composites, Plastics, and Advanced Materials CNC Machines

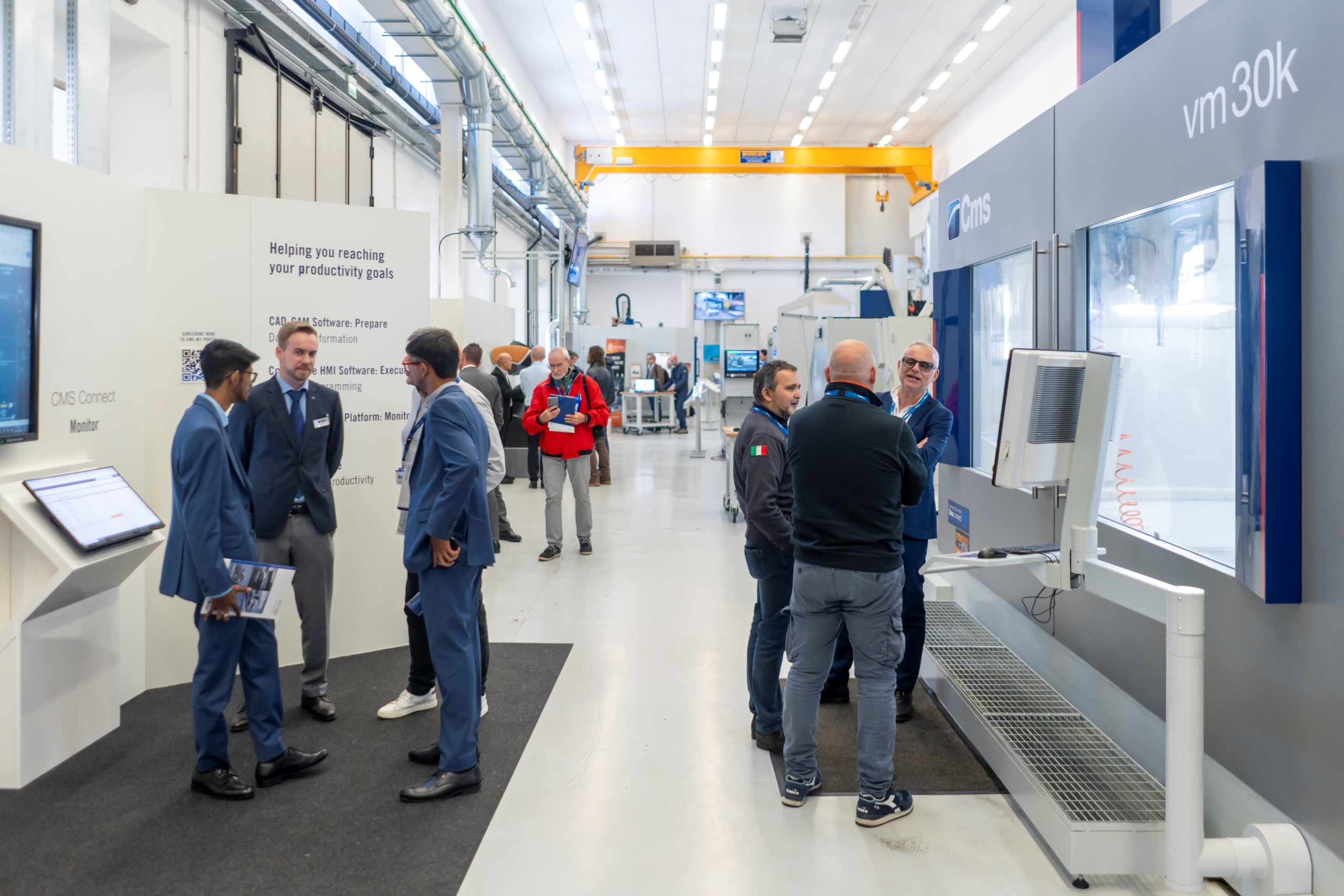

Advanced Materials and Plastics is one of the most dynamic manufacturing sectors in the world. Last month, CMS hosted an exciting Open House to unveil their latest innovations in the space – and they didn’t disappoint.

Hosted at CMS’ Plant Z facilities in Zogno, Italy, the event featured live demos of the new and upgraded machines. Two demo sessions were hosted across all three days, with CMS technicians on board to answer questions.

Have a read of the below if you missed out – we’ve summed it all up in a quick read.

New and upgraded composites CNC machines

Plastics manufacturing spans everything from milling, drilling, trimming, and cutting – all of which plastics and composites CNC machines do. A selection of CMS models were tweaked for this purpose, increasing productivity and performance across a range of functions.

First up on the list, we have the Athena, a 5 axis CNC machine for trimming. This popular model is used in tandem with thermoformers to finish products off with high precision and accuracy. A very in-demand machine, as our reps have seen!

Next up, the Tracer 200X, a hybrid machining centre integrated with a blade/saw was another enhanced composites CNC on display at the open house.

The CMS Antares was one of the most highly anticipated CMS models when it launched – and now, it’s even better. The advanced materials CNC is known for superior 5 axis machining – and it’s easy to see why. Compact design, a sturdy monobloc structure and a large working table are the base elements that contribute to its success, along with high-precision and automated loading/unloading. It’s the perfect mix for reliable, steady production.

For those looking to maximise floor space while maximising 5 axis CNC milling, the ultra-compact RT-F 1400 is a great option. Made by H.G Grimme, the rotary table on this model means the machine goes non-stop, churning out parts with speed and accuracy.

As for those interested in light alloy machining, the upgraded Tao-x is worth looking into.

Thermoforming and additive manufacturing machines

The Eidos, a heavy-gauge vacuum former, is one of our most popular thermoforming machines to date – and it’s now even better. Be sure to chat with our reps or ask them for the new spec sheet for technical details.

While CMS is relatively new to the additive manufacturing space, they made a splash when the Kreator, a large-format milling machine + 3D printer hybrid entered the market. This year, they’ve launched a specialised machine made for large-format additive manufacturing – the kreator a3.

Using Screw Extrusion Additive Manufacturing (SEAM), the a3 prints large-scale parts out of PC, PEI, ABS, carbon and glass-reinforced PLA, plus more. With a working table that measures 2500 – 9800mm on the X axis, 2500mm on the Y axis, and 1300 on the Z axis, aerospace, automotive, and marine manufacturing is set to break new boundaries.

If you’re curious to learn more about these machines and want to hear about how they’re being used, ask our reps. We’re constantly on the line with CMS and have plenty of real-time insights to share with you. Call our office on 1300 404 512, or reach out to our reps via email or mobile directly.