Glass Manufacturing Trends 2026 and Beyond

The Australian glass industry is at a turning point. With Oceania Glass ending its century-long legacy, a new chapter is opening up for local glass manufacturers. One where speed, supply chains, and strategy are becoming increasingly important.

While domestic glass manufacturers are navigating a post-Oceania Glass market, a number of new trends are emerging. We saw them pop up, both at AusFenEx 2025 and Vitrum 2025 – and globally, too.

Here’s a deep dive on the insights, just in time to help you plan your strategy for the year ahead.

The global glass manufacturing supply chains shuffle

With rising costs affecting much of the Western world, glass manufacturers are sourcing panels from lower-cost destinations. The shift in sources has a massive impact on supply chains, and the flow-on effect is felt on a day-to-day basis.

The result is a need for better inventory management; from sourcing to storage. Some businesses are doing this with sophisticated software; others are using plain old Excel spreadsheets. Either way, the level of management is becoming more advanced, and as things stand, this trend is here to stay.

Automation and digitisation

It’s no surprise that there was major talk about automation and digitalisation at AusFenex and Vitrum. Software engineers and IT experts are increasingly becoming key players in glass factories, stretching the capabilities of existing machinery to new levels. Civic Shower Screens’ Elton Lockhart is a prime example of this – and his insights are well worth checking out.

In a high-speed, repetitive setting like a glass manufacturing factory, software plays two key roles:

- To optimise the controls for machinery, and

- To collect valuable data that can be analysed for further optimisation opportunities

The more sophisticated the setup, the more opportunities for growth. It’s no longer enough to have the most advanced glass CNC machines in your factory floor. You now need the human brainpower to leverage the machine’s capabilities, look at the overall workflow, and find ways to make it better. That’s the new gold mine in glass manufacturing.

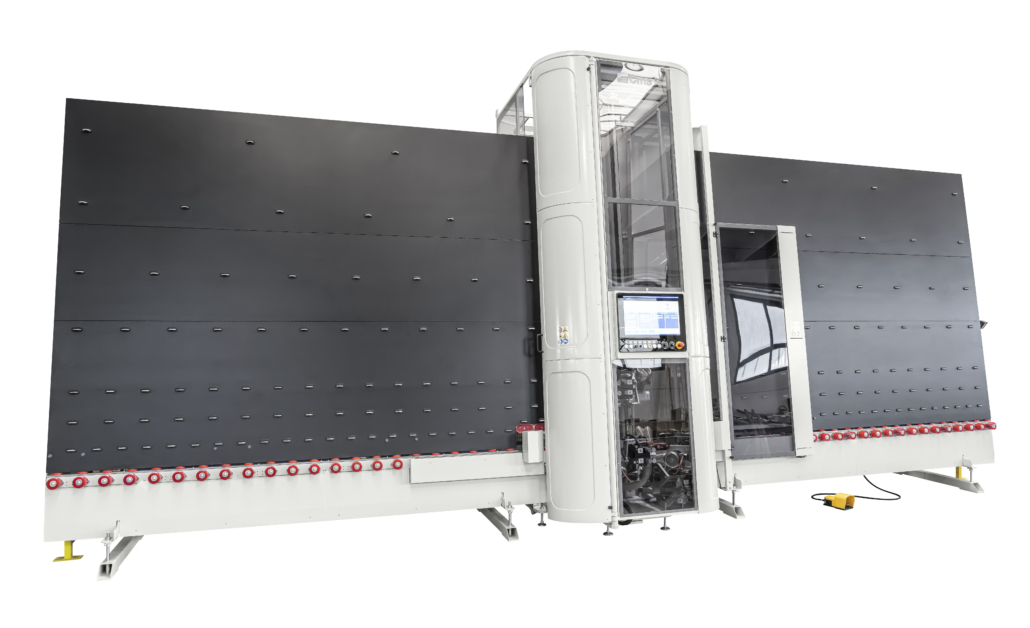

In many cases, that means upgrading to something like Bovone’s automated lines – or bringing robotics into the shop. Robots are ideal for the high-repetition cycles in glass, and they can be easily trained to take on a range of tasks.

If you haven’t already explored Bovone robots, we suggest you check out what they’re capable of.

Sustainability

With a push to produce in the most energy-efficient way possible, glass manufacturers are aligning with sustainability goals. Lower overheads are the main motivating factor to minimise energy usage – and the impact can be massive.

A glass CNC like the Aura is a smart choice, with dry-seaming capabilities for everything from laminated panels to low-E coatings. Without the need to use water during the production process, its sustainability and cost-saving benefits are well aligned with both industry and business goals – and the quality is unparalleled.

Also on the theme of sustainability, double-glazing continues to be a trend in Australia, brought on by the updated Building Code regulations.

Success starts with strategy

Change often stirs up uncertainty but it also brings in opportunity. While there’s something to be said for sitting back and observing the aftermath of change, speed is the one habit that all successful firms no matter the industry carry.

That isn’t to say that rash actions lead to success. Rather, taking stock of what’s going on, rapidly creating a winning strategy, then executing on it ASAP is the way to go.

If you’re looking to do just that and need insights or advice, we’re more than happy to help. These are exciting times, and we’re hearing lots of innovative strategies popping up. Will you be the talk of the industry?

We hope so. Reach out and let us know where you’re headed – we’ll happily lend our insights and expertise to your get there.

Get in touch

Looking for the right product for you, reach to our experts and let’s chat.