CMS MasterForm

A winning solution. Everything in a small place

Specifically created for long-fibre composite material thermoforming, it works with a clamp torque up to 100 tons, ensuring the best moulding result also in case of complex shapes and tight corners. Extremely versatile and easily manageable by a single operator, it reduces the setup time and allows rapid production changes.

- versatile: the machining centre enables extremely fast set-up and can machine non-composite materials too. Versatility is enhanced by the heating system which operates on the two sides of the sheet.

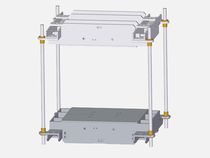

- compact: the structure ensures limited overall dimensions and is equipped with a special integral moving table system, which enables realizing an interlock between the two die halves.

- functional: the machine can be controlled by a single operator as the functions are all automated and self-programmable.

- dimensions: from1.500×1.200 mm up to 3.000×2.000 mm

Advantages

THERMOFORMING MADE EASIER

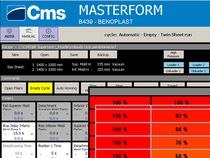

Simple management of all process parameters thanks to a userfriendly software specifically developed for thermoforming process. It shorter by 53% learning times compared to different solutions. All variables are saved in a single program ensuring the same results even after years.

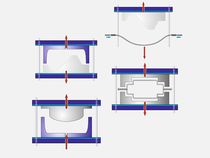

TWINSHEET TAILOR MADE

Twinsheet process is possible thanks to two heating stations. Each heating station is equipped with a double (upper and lower) heating system for a total independent management of the two sheets, ensuring optimal heating even with different thicknesses and colors, allowing total access to the internal surfaces for installing internal parts or cores.

BEST-IN-CLASS ACCURACY AND PERFORMANCES

Mould tables driving system with shared columns that guarantee perfect alignment without any centering devices. Tables movement is made with 8 brushless motors with an addition of a hydraulic interlocking system that allows to reach high closing force values up to 120 tons adjustable by software.

FLEXIBILITY ALL AROUND

Single plate mode is possible with vacuum and pressure forming processes both in standard mode or pendular cycle with the use of the second heating station to heat up the sheet while forming and cooling the previous one. In this way you can reach productivity values up to 63% more than the single station version. Possibility of sheet stretching during heating and/or forming.

Technical Data