CMS TECNOCUT PROLINE

Hydro-Abrasive waterjet cutting system

The ultimate machine tool specifically conceived and designed with advanced technical solutions for the waterjet cutting technology, in order to achieve unmatched performance. Proline is built around a stainless-steel frame ready for integration with the “Dredge”, a fully automated and maintenance free abrasive removal system, an automatic water level control for submerged cutting and rotary option for pipes processing. This innovative, easy configurable concept has the abrasive tank installed on-board, a big saving in terms of overall layout. The overall machine structure, especially the rugged gantry system, offers unmatched rigidity and thus consistent cutting accuracy over time, thanks also to the ground helical rack and pinions, combined with high precision gearboxes.

The linear guides are protected by the innovative “Powder free” system composed of overlapping way covers, which ensures the highest protection against moisture, dirt and dust.

- More versatility: new models and extensive supply of accessories and standard arrangements for faster, less costly retrofits

- More reliable: NC and digital drivers for full control of the cutting parameters

- More compact: accessories integrated into the base structure for easy, fast installation and re-commissioning

Advantages

-35% OVERALL DIMENSIONS

– 35% of layout with respect to previous models, thanks to the integration of the abrasive bulk and high-pressure pump.

HIGHEST PRODUCTIVITY AND CUTTING VERSATILITY

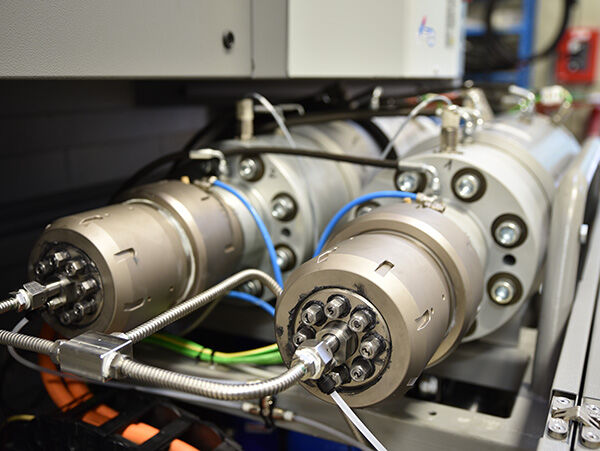

It can be fitted with up to 2 electric and servo-driven pumps, 4150 or 6200 bar available pressure, with the aim to achieve the highest throughput and cutting versatility also when working especially hard or thick materials.

READY FOR EASY INTEGRATION WITH OPTIONAL

Machine is ready for easy integration with optional such as the Dredge, the rotary option and the water level control for submerged cutting, to accommodate specific applications and the most demanding production requirements.

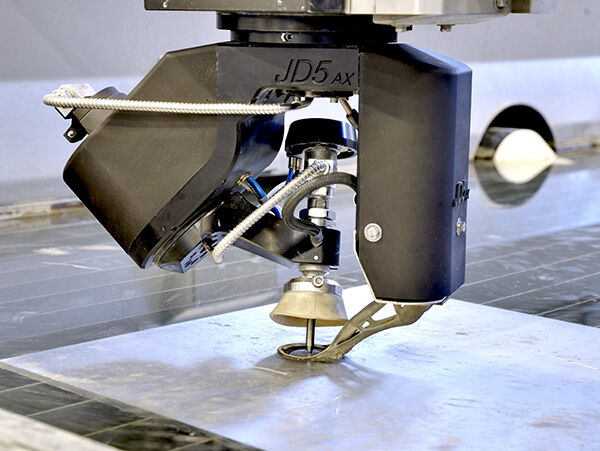

UNPARALLELED CUTTING QUALITY

± 0.035 mm of positioning accuracy and +/- 0.025 repeatability across the entire table, to ensure unparalleled cutting quality

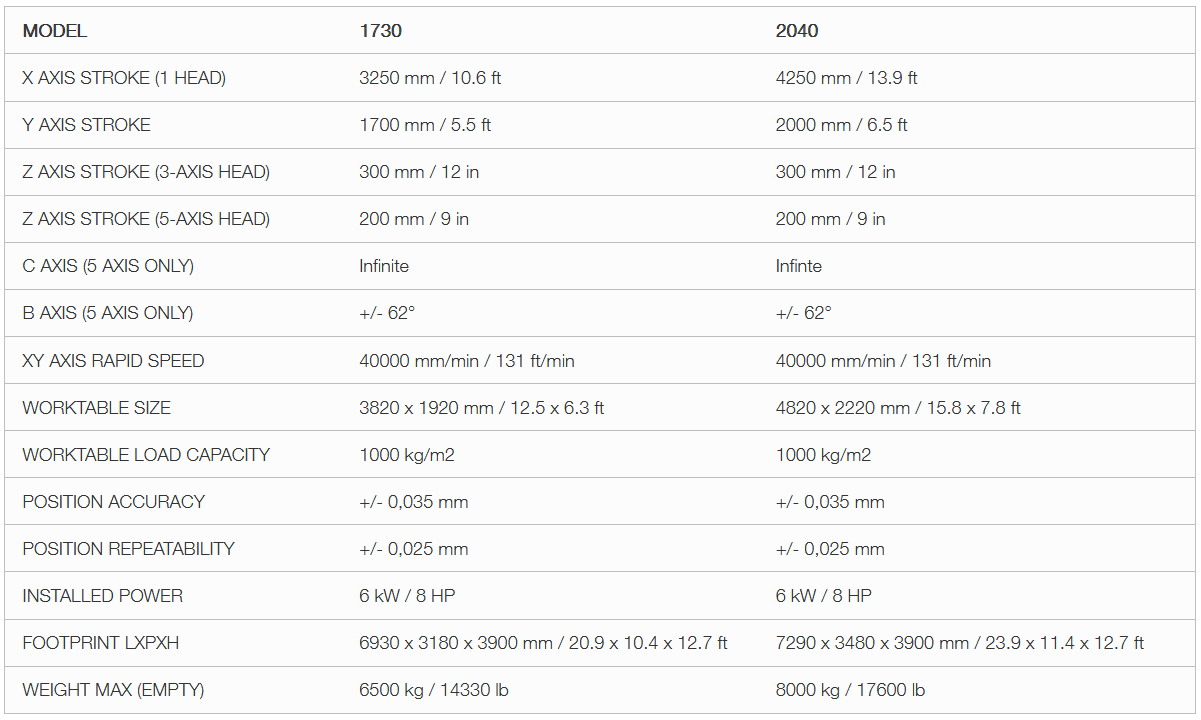

Technical Data