CMS Time 100

CNC machining centers for plastic materials processing

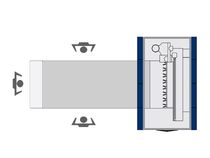

Machining center designed and engineered for plastic materials processing Due to the unique design and Pro-Space safety systems, it requires less floor space and can be operated from all sides for material handling of smaller components.

- high performance, essential and flexible 3-axis machining centre with advanced technical solutions and an incomparable performance/price ratio

- high level performance able to combine, in a unique way, the needs of all sectors of plastics processing, from signage to nesting to the technical article

- compact size thanks to our “pro-space” solution

Advantages

MINIMUM ENCUMBRANCE MAXIMUM ACCESSIBILITY

Thanks to the “pro-space” protections the loading area is absolutely unobstructed in order to minimize the space occupied.

The absence of perimeter protections enables accessing the work surface from all machining centre sides.

SPECIALIZED WHEN NEEDED

A range of dedicated heads and special devices for graphic reference survey increase the machining centre specialization without renouncing the performance of a mobile gantry structure of higher class.

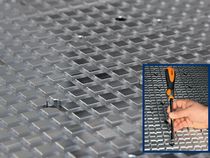

FIXTURES AND FORMAT CHANGING IN RECORD TIME

The worktable is sturdy, practical and non-deformable due to the laminated aluminium structure; it is also equipped with the widest range of mechanical clamping devices. The worktable is equipped with the exclusive magnetic system for vacuum closing, which enables an average 25% saving in localizing the workpiece positioning area.

LIMITLESS MACHINING WITH INTERPOLATING VECTOR AXIS

Absolute freedom in tackling even the most complex geometries, as it is typical of plastic components. Automatic 360° rotation and positioning on the X-Y working plane of the angular transmission heads by means of the NC digitally controlled interpolating Vector axis.

Technical Data

*stand alone/with pusher