Dal Forno | Vacuum lifters | OMNIA | flexible pad

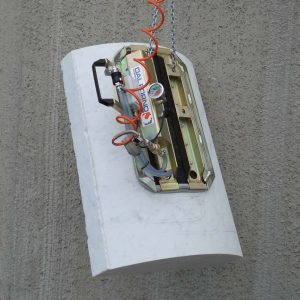

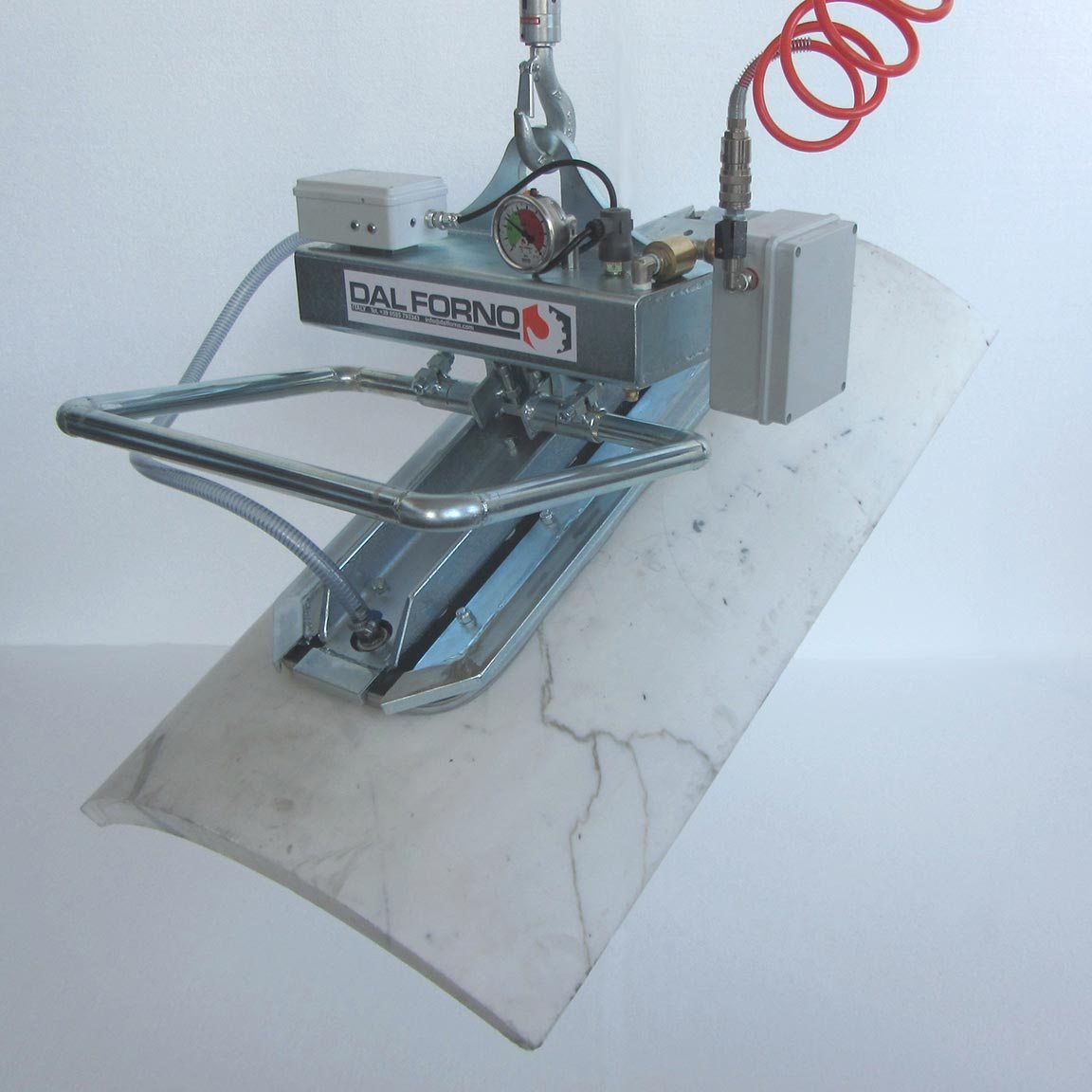

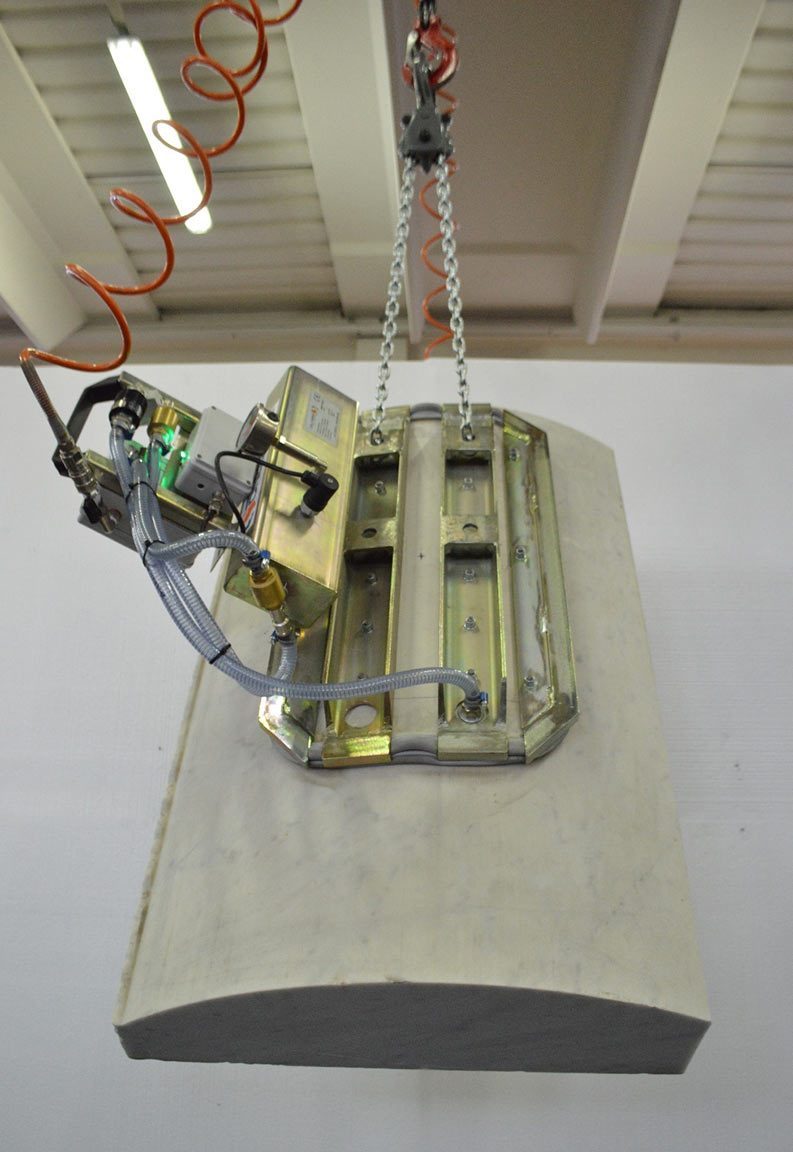

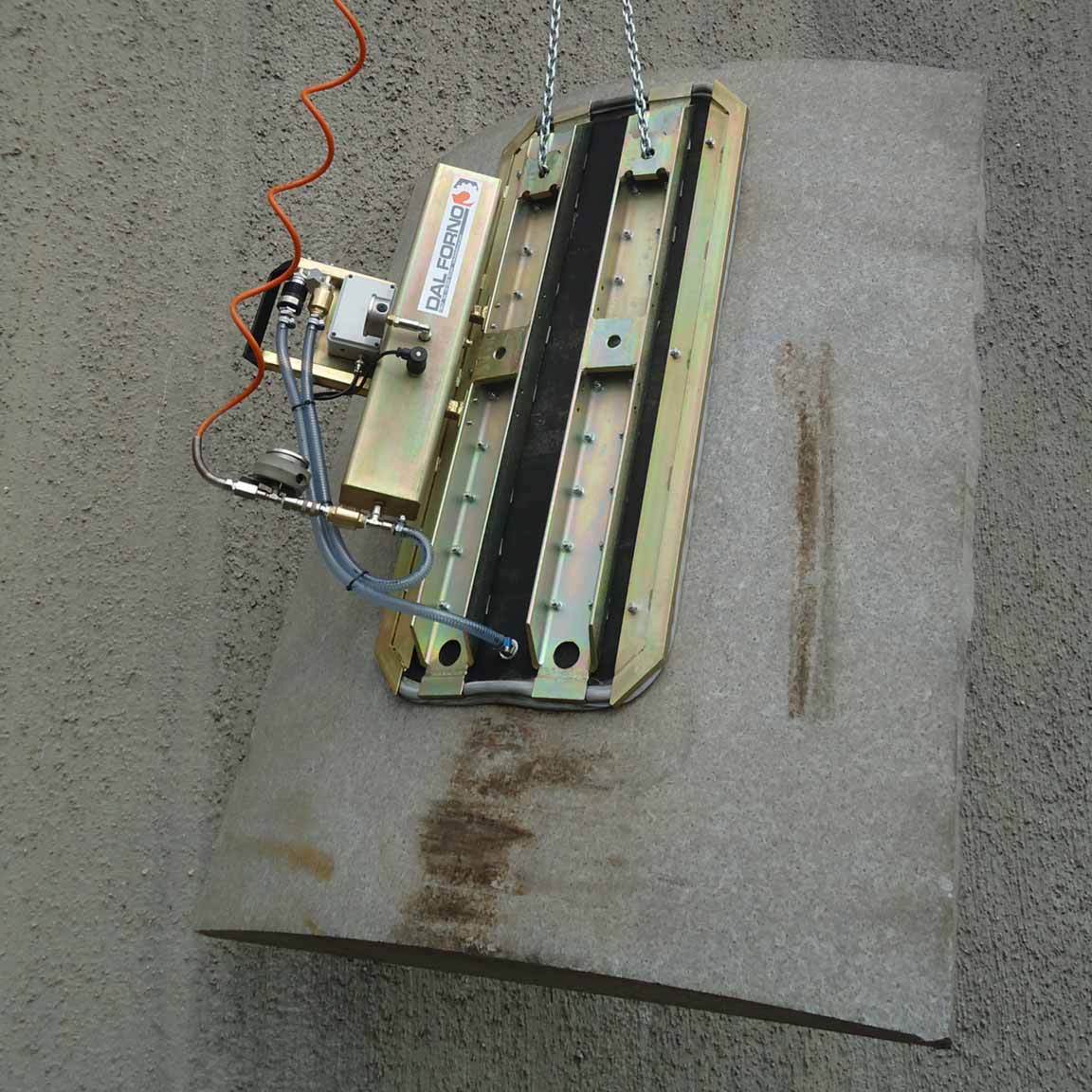

Flexible pad vacuum lifter

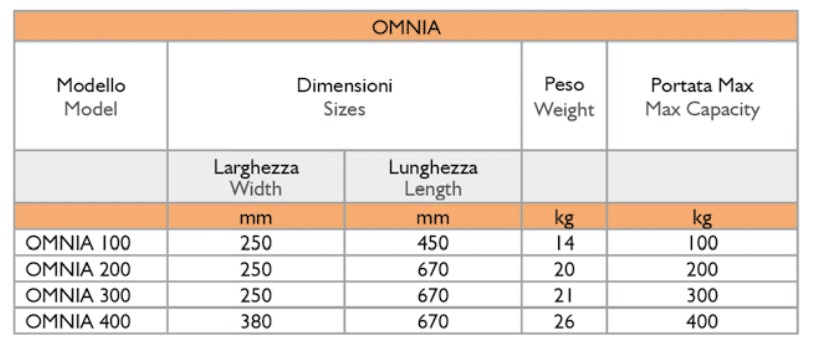

Capacity: 100 to 800 kg

Suitable for lifting column sectors, cylindrical shells, both concave or convex, polished or rough.

The focus on the implementation of the latest production technologies and the examination of the handling demand relevant to the most different shapes of modern elements leads to the design and the production of a flexible suction pad with variable deformation (PATENTED). A high tech accessory with great flexibility. Safe and manufactured with composite materials, make this vacuum lifter an innovative solution for lifting and handling of curvilinear products.

A big step ahead is our distinctive rubber sealing, flexible, resistant and long-lasting, that allows gripping of any material finishing (raw, polished, honed, flamed, bush-hammered, sandblasted, etc.)

Advantages

Features:

- manufactured with light alloy materials and galvanized steel, aluminium casting pad – long-life and rustproof;

- fast and easy replacement of the rubber sealing ring;

- can be tilted 0° to 90°, to lift and lay down materials both horizontally that vertically (upright);

- pivoting axis close to the pad to facilitate the vertical positioning;

- adjustable inclination of the manoeuvring handle;

- detachable and rechargeable vacuum leakage alarm with buzzer and warning lights activated by a vacuum switch, apart battery charger;

- one-direction valves to allow vacuum keeping also in case of pipe cuts/vacuum loss;

- ON/OFF sliding valve with locking device against accidental releasing;

- in compliance with the CE Machine Directive to conform the EU standards for CE marking.

Feeding options:

The vacuum is generated by an electric pump or by means of a compressed air vacuum generator (Venturi pipe). The unit usually consists of: electric vacuum pump + connecting pipe + vacuum suction pad. The vacuum pump is to be placed nearby the working place. For special application can be supplied pumps with single-phase, DC electric motors (to be installed on fork lift and hydraulic crane), internal combustion ones.