Robotics in Manufacturing: A Fad or The Future Norm?

Robotics is a hot topic right now – and it’s taking the Australian manufacturing sector by storm. Some are enthusiastically embracing the technology and seeing major productivity benefits from it. Others are reserved. wondering what effect these ultra-high productivity tools could have on workplace dynamics. The truth is: manufacturing robots are a nuanced topic, and worth exploring in detail.

In this blog, the first of a series on the topic, we’ll be scratching the surface on robotics in manufacturing and their widespread effects. Over the next few months, we’ll dive deep into main subtopics, giving you plenty of food for thought. Let’s begin, shall we?

Factory robotics: friend or foe?

For decades, robots have captured people’s imagination. Nikola Tesla, the Master of Lightning, saw them as a key part of our future, citing that “automatons” would be part of our everyday lives, just as his brilliant inventions are today. He was right. Now, they’ve reached Australian shores; and they’re causing controversy.

It’s not the technology itself that’s causing a stir. The value of the robots in factories is clear to all. The quality of their output is excellent, especially for repetitive tasks that workers could develop repetitive strain injuries from, or just find boring. Safety and quality are major advantages that any factory benefits from. So, why would some be hesitant to take on technology that increases both, plus raises overall productivity? The answer lies in human connection.

Man and machine

One thing is certain in life: there will always be change. And when one change happens, another follows. In the context of installing manufacturing robots, many worry that the flow-on effect would mean letting go of staff. It’s a valid concern – at least, in theory.

In practice, we see a different phenomenon taking place. The majority of businesses who have invested in industrial robots have actually brought on more staff. Yes, you read that right. The productivity gains have allowed them to grow and bring more people into the business, expanding even further. The low-level jobs have been taken over by automated solutions – which leaves room for people to tackle the more complex tasks.

Opportunities open up when man and machine strategically work alongside each other. The key is to have a clear vision of where you want to go, then find the most efficient way of getting there. That’s where we come in.

Join the robotlution

Fast-growing companies have already integrated robotic cells as part of their long-term productivity strategy. Their high yields, 24/7 operations, and ability to keep workers out of harmful, dusty environments are key selling points for decision-makers who have their eye on the future.

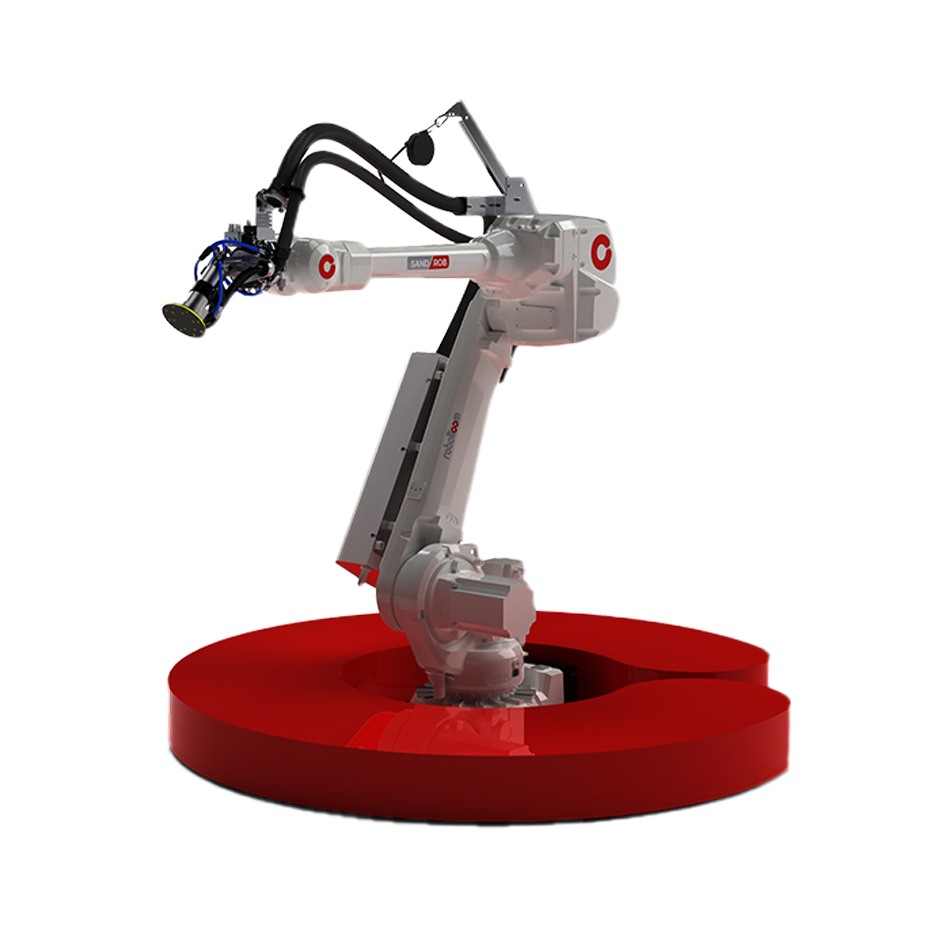

Technology like Roboticom’s Sandrob, a recent addition to our collection, have made a major impact in the Advanced Materials & Plastics space. As a side effect of the productivity and time savings, employees are free to explore innovative solutions, fuelling growth at speeds previously not possible.

We are seeing transformations happen left, right, and centre, with major benefits for those tho embrace the change. It’s not for everyone – but neither are some of our CNC machines. It all depends on the purpose, context, and long-term goals.

Stay tuned as we dive deeper into the specifics of how robotics in manufacturing brings unparalleled growth in the next chapter of this series. In the meantime, feel free to ask for real-life case studies from our reps – there are more coming in every day.

Get in Touch

Looking for the right product for your business? Get in touch with our experts and let’s start the conversation.