3 Low-risk CNC machine investments for a dynamically changing world

Making investments is tricky business. Especially if you’re a manufacturer in today’s volatile world. To succeed, you need a blend of great analytical skills, pragmatism, and the financial literacy to save, borrow, and spend wisely – plus a very clear idea of what you want and need from the technology itself.

No need to worry. We’re here to help.

With a broad-spectrum view of the trends and innovations across the Stone, Glass, and Advanced Materials and Plastic industries, we’ve got a good idea about which investments pay off. While each individual case requires us to carefully analyse your business, production runs, and the current setup you’re carrying, we’re happy to share our most versatile machines and accessories, picked specifically for a dynamic market. Pay close attention – these items are true game-changers!

1. Waterjets are the chameleons of the CNC machine world

It’s true. There’s almost nothing a waterjet can’t cut – and in some cases, they’re the only kind of CNC machines we’d recommend you use. Especially if you want a low-risk option for cutting sintered materials like Dekton…

With CMS’ advanced software hosting an expansive materials database, it’s easy to set jobs up and go. The fine-tuned controls for garnet flow, water pressure, and speed allow you to switch between materials with minimal effort. You can even save the settings – a very handy feature that helps get more done in a day.

Our most popular models include the Easyline and Smartline, both of which we stock in our showroom. If you want a hands-on look at what they’re capable of, give us a call to set up a demo session; either in Sydney or our new Queensland branch.

2. Materials handling solutions

Over the past few decades, the trend in materials specifications has been an increase in size. Architects love to create seamless spaces using large panes of glass, big stone slabs, and continuous metal sheets. In order to cut and manage them, manufacturers have turned to more sturdy and sophisticated materials handling solutions.

Automated storage solutions like those from TUROMAS allow safe storage and handling of jumbo-sized glass – leading to secure transfers to the cutting table using a set of hydraulic tilting arms. By decreasing the manual intervention of glass handling, the operators’ safety is greatly increased, while frequency of breakages is decreased – a win-win in every way.

For stone processing factories, the range of Dal Forno vacuum lifters and stone handling equipment is a worthwhile investment. Coming in all shapes and sizes, they handle everything from large but thin ceramic slabs to curved stone pieces without a problem. Those who have them will tell you that these vacuum lifters bring physical labour down to a minimum, allowing workers to channel their energy elsewhere.

3. Advanced CNC machine software

The digital elements behind CNC machines are just as important as the hardware itself. With greater control over production runs, operators are able to position, time, and run jobs in more efficient ways than ever before. Plus gain analytical data that can help streamline jobs in the long run.

For thermoformers, CMS’ patented solutions in the form of ThermoProphet and ThermoActive software have been a breakthrough in the Plastics space; giving operators an Interface designed for ease-of-use as well as an intelligent dynamic heating control to ensure consistent forming quality, no matter the conditions.

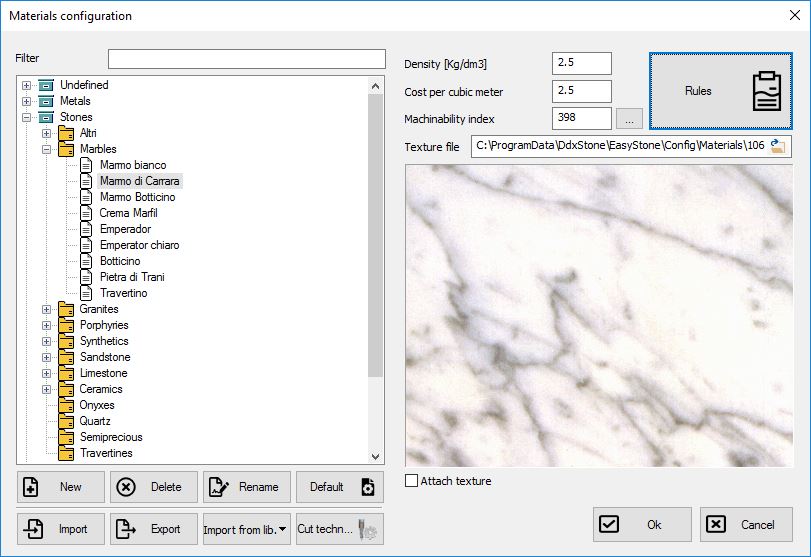

In the Stone and Glass sectors, all our CNC machines are equipped with solutions from the DDX Software House. Founded by former CMS engineers over 10 years ago, the line offers a range of software solutions for CAD/CAM on CNC machines, waterjets and more; as well as dedicated benchtop programming and production management systems. The programs are designed to boost the digital operations even further; helping you plan, program, and manage the workflow from start to finish. The best thing is, these solutions interface with almost all machines in the market, enabling full and complete integration.

If you’re wondering how to maximise your current setup without making big changes to floor plans, these products could be the answer. Let our reps know what you’re looking to achieve and we’ll find the most efficient way to get it done. Trust us to offer options that hold lasting value, even in the rapidly changing world we live in today.