Glasstec 2024: Cutting-Edge Technologies and Industry Trends

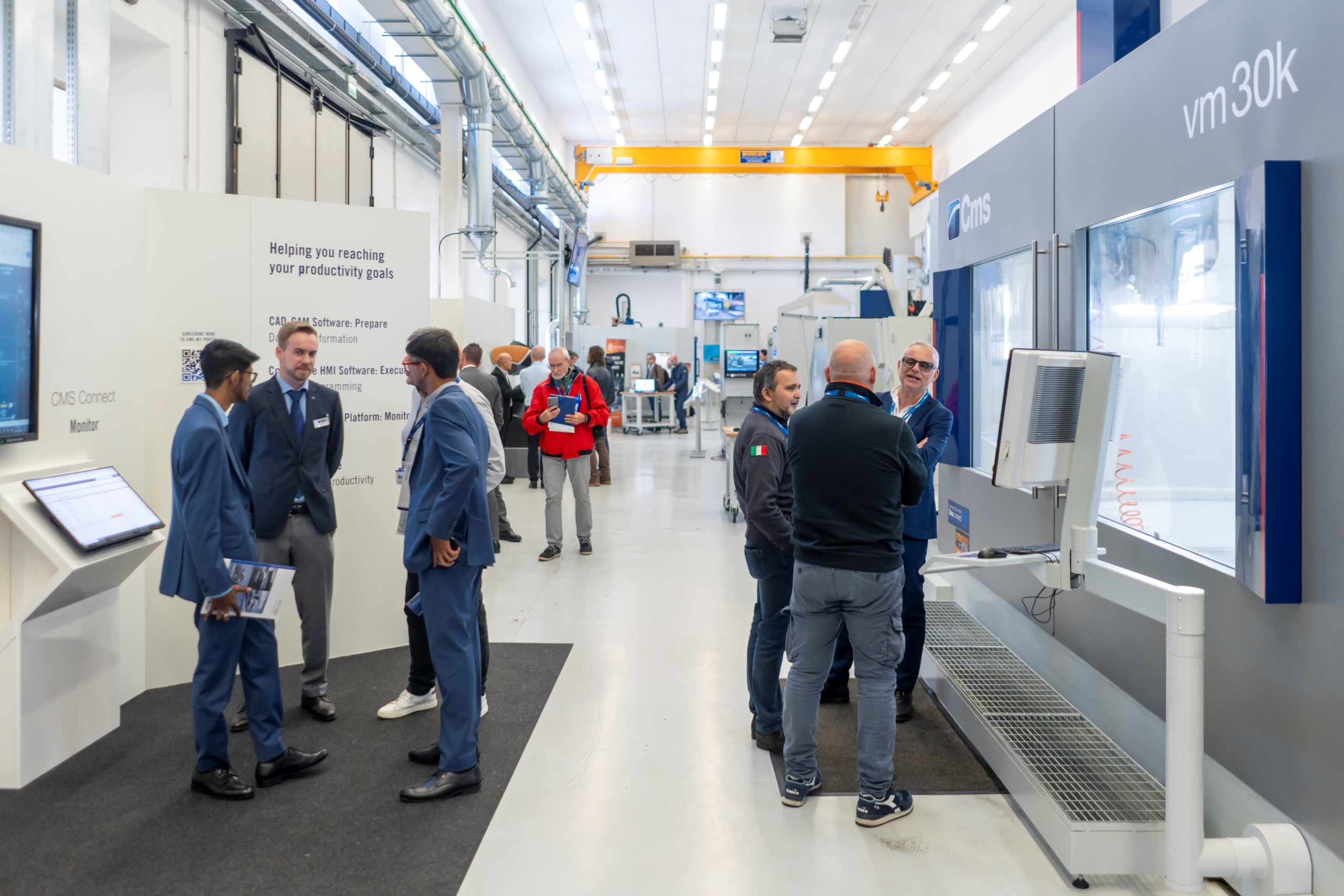

Every two years, Messe Düsseldorf transforms into the global hub for glass professionals. Glasstec, the world’s largest biennial trade fair for glass machinery, tooling, architectural innovations, and industry insights, brings together thought leaders and cutting-edge technologies. This year, Innovync was at the heart of the action.

Our Managing Director, Pierre Sullivan, and Stone, Glass & Tooling Expert, Dominik Holfter, returned with exciting news on the latest innovations from CMS and valuable insights into where the glass industry is heading.

Read on to discover all the highlights!

Latest Glass CNC Machines and Technologies from CMS

This year, CMS introduced three exciting new machines: the Taktika, Proxima, and Agil Lam Cutting Table. Let’s dive into what makes these machines stand out.

Taktika CNC: An Entry-Level All-Rounder

The Taktika is a highly flexible vertical CNC designed for machining glass panels ranging from 320mm to 3100mm (height) and 220mm to 2000mm (width). As long as one straight edge is available, it can handle shaped pieces with ease. The Taktika is capable of milling, drilling, countersinking, seaming, grinding and polishing, making it a true all-rounder.

This compact machine is ideal for companies looking to introduce the benefits of Vertical CNC processing without the traditionally high investment. Its processing versatility while maximising space efficiency and enhancing productivity, makes it an excellent choice for various glass processing needs.

Agil Lam: Automatic Cutting Table

In line with its commitment to innovation, CMS has unveiled the Agil Lam Cutting Table, an automatic solution for cutting laminated glass panels up to 8+8mm thick. This prototype, designed with ergonomics and user experience in mind, is set for release early next year.

The Agil Lam features an intuitive software interface that allows operators to save and initiate jobs with a single click, reducing time-consuming tasks and enhancing efficiency. This advancement aims to make glass processing quicker, smoother, and more efficient than ever.

Proxima: Semi-Automated Seamer

While the Agil Lam is fully automated, the Proxima offers semi-automated functionality, specialising in dry seaming panels up to 2600mm long. This horizontal machine can be placed adjacent to a break-out table and allow quick arrissing during the breaking out of glass sheets. This makes it an ideal pairing for float and laminated glass production lines, including the Agil Lam.

Speak with our sales team to explore which machine best fits your specific needs.

Glass Industry Trends: Sustainability Takes Center Stage

In recent years, architectural projects have increasingly focused on energy efficiency, particularly with double or triple-glazed windows to meet LEEDS certification requirements. However, at Glasstec 2024, the conversation shifted towards a broader goal: sustainability.

This year’s discussions highlighted two key sustainability trends—circularity and decarbonisation. Both play a crucial role in the full lifecycle of glass production and use. As building regulations in Australia evolve to align with global sustainability goals, the glass industry faces new challenges and opportunities.

We saw machinery manufacturers launch the first-ever IGU recycling machines, that can separate an old Insulated Glass Unit into its individual glass panels and allow re-purposing of the glass for a new unit. This will benefit particularly countries where old & ageing insulated windows need updating to new standards and will allow cost savings to the home owner.

At Innovync, we embrace these changes. We’re dedicated to staying ahead of the curve and helping our customers navigate the future of sustainable glass production.

Want to learn more about these technologies and trends in the glass industry? Contact us today for more insights or to speak with one of our experts. You can call us at 1300 404 512, and our team would be happy to help.