CMS Brembana Kartesia

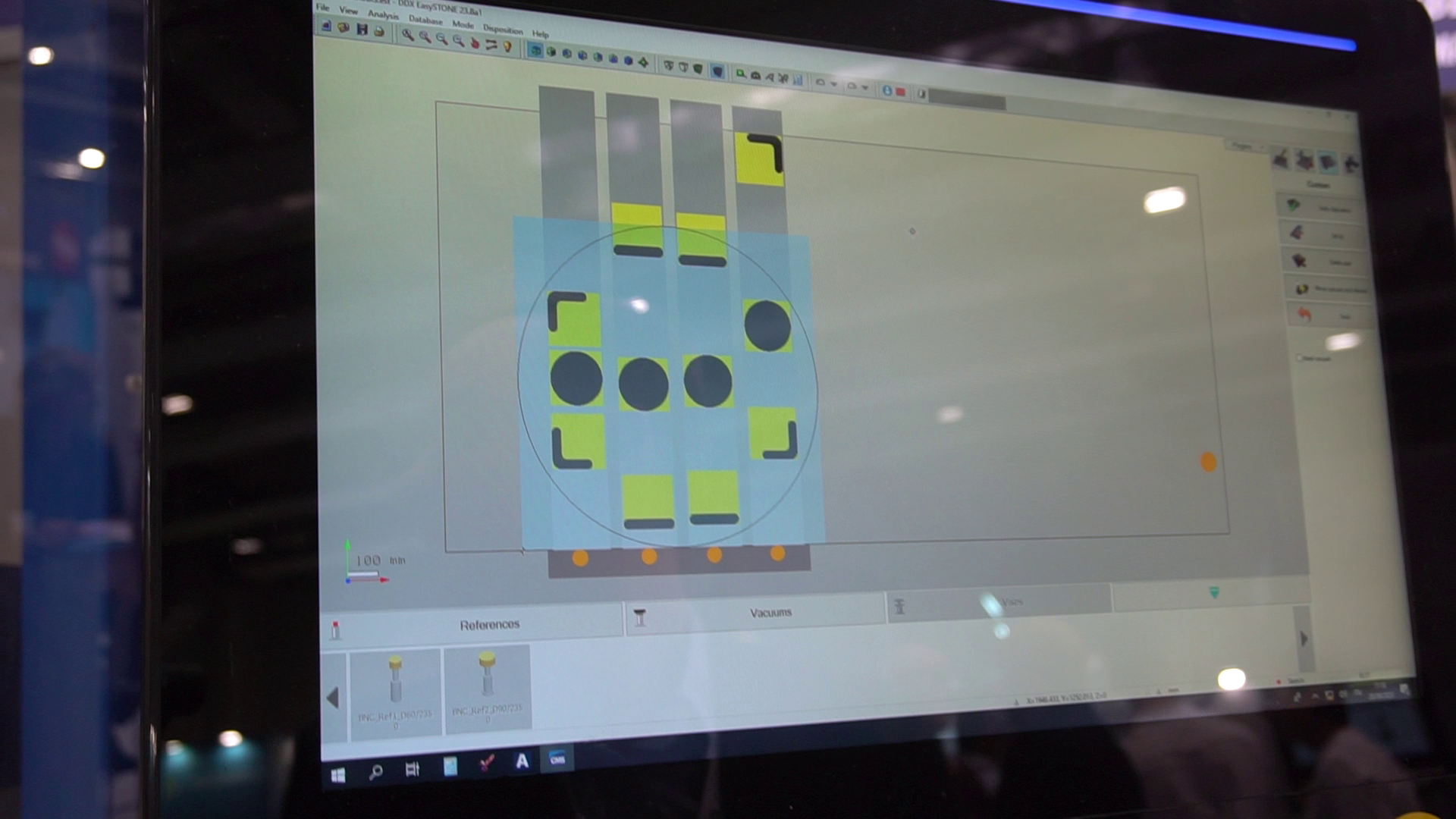

3- or 4-axis numerically controlled machining center with automatic stop and suction cup positioning system

brembana kartesia f is the most compact and revolutionary three/four-axis interpolated machining center operated by Numerical Control for processing marble slabs, granite, synthetic stone and ceramics. This machine is the ideal solution for quickly and accurately performing any kind of edge contouring, rough or polished, milling, drilling, countersinking, bas-reliefs and lettering.

Worktable tooling is handled fully automatically by the machine and does not require any human intervention: this solution significantly increases productivity while ensuring a small footprint.

Advantages

-71% HUMAN INTERVENTION

The operator will no longer have to worry about worktable tooling times, which will be fully automatic and managed by the machine. In the free time gained, the operator can focus on other workshop activities.

+26% PRODUCTIVITY COMPARED TO A STANDARD MACHINE

With the same amount of floor space occupied, the machine will no longer have to wait for the worktable to be tooled, since it will do so itself in a very fast and fully automatic manner.

ERGONOMICS AT THE FOREFRONT

The complete elimination of visible air/vacuum piping and the height of the worktable contribute to improved ergonomics for daily workpiece loading/unloading operations.

UNSURPASSED MECHANICS

The strong structure of these machining centers ensures optimal stress absorption due to the machining, guaranteeing high precision over time. The base fixed directly to the ground, without the need for masonry work, increases the stability and the performance of the machine.

Technical Data