CMS FXB

Fixed bridge machining center with 3, 4 or 5 interpolated axes

Machining centre with 3, 4 or 5 interpolated axes, specifically designed for high speed machining of large pieces in light alloy materials, composite materials, impregnated fibres, sand-based, and wood-based materials.

The benefits of fxb:

- strong, rigid and very accurate mechanics

- wide range of machining units with tool change facilities

- high productivity and zero downtime

- optional multiple independent operating units

- productivity and quality

Advantages

QUALITY OVER TIME

The advanced design of the structure, a result of CMS’ research centre, and the technical solutions adopted, such as roller recirculation and gantry motorization, guarantee rigidity and precision over time so that the high finish and accuracy of the workpieces remains a constant feature of your production over the years

POWER AND PRODUCTIVITY

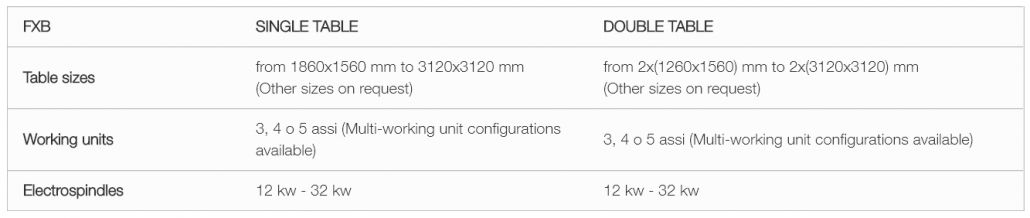

FXB can be equipped with single or multiple operating units, with 3 or 5 axes and power up to 32 kW to ensure maximum efficiency in every production reality.

All the electrospindles are fully designed and constructed within the group and are the result of 30 years of experience and ongoing innovation. The wide range allows our Customers to always choose the electrospindle that provides the ideal torque, power and speed for their own machining requirements, thus enhancing the productivity of their machining centre.

Dedicated units are available for special applications, such as the processing of stacked aluminium foils or for laser marking of finished workpieces.

360° CONFIGURABILITY

The FXB series is available in over 30 versions with single or double table configurations and the worktable can be further customized with the most efficient clamping systems for individual production requirements.

The same geometry of the machine allows a highly productive management as it is possible to load/unload without stopping operations and access the working tables in total safety for the operators.

Technical Data