Dal Forno | Vacuum lifters | X series | pneumatic tilting

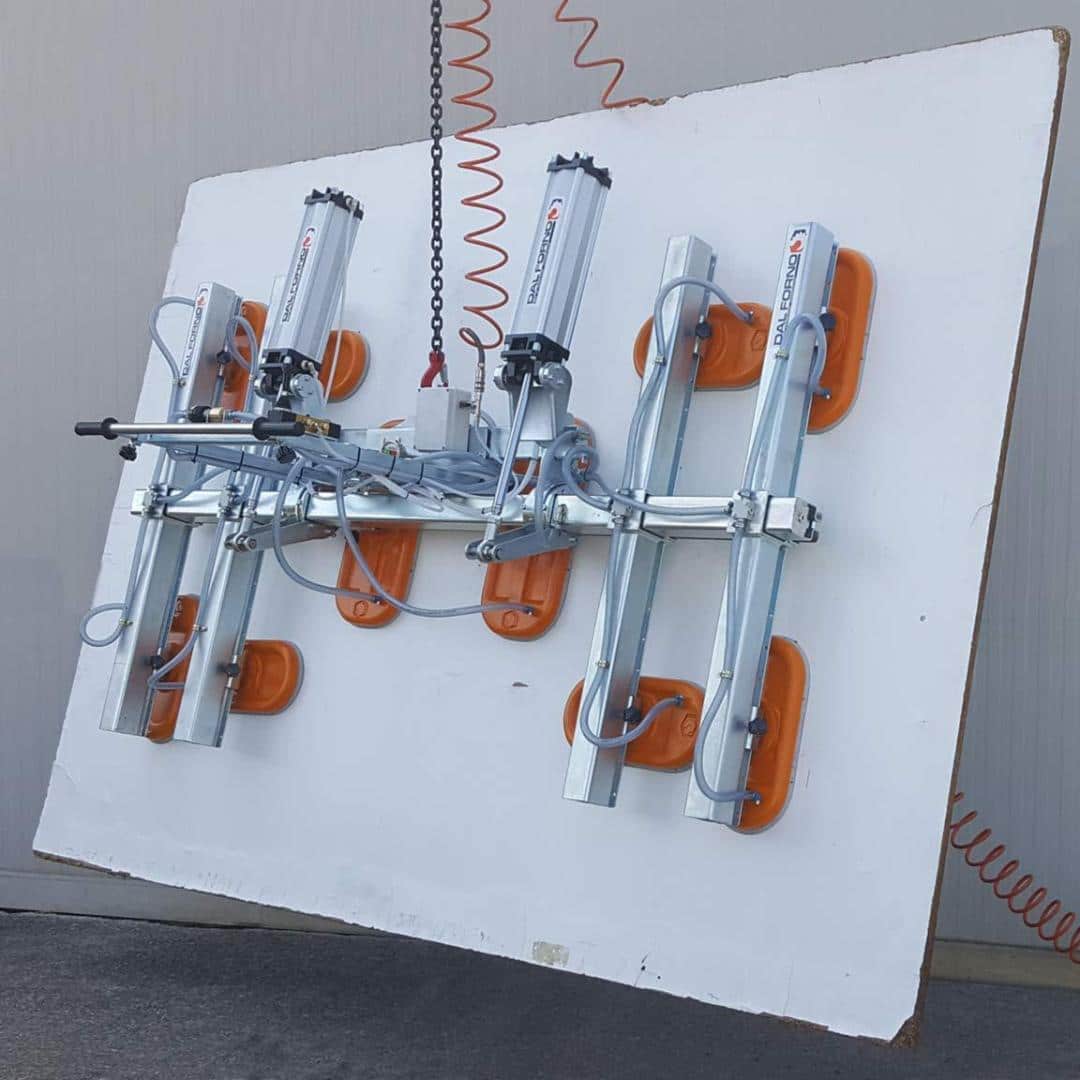

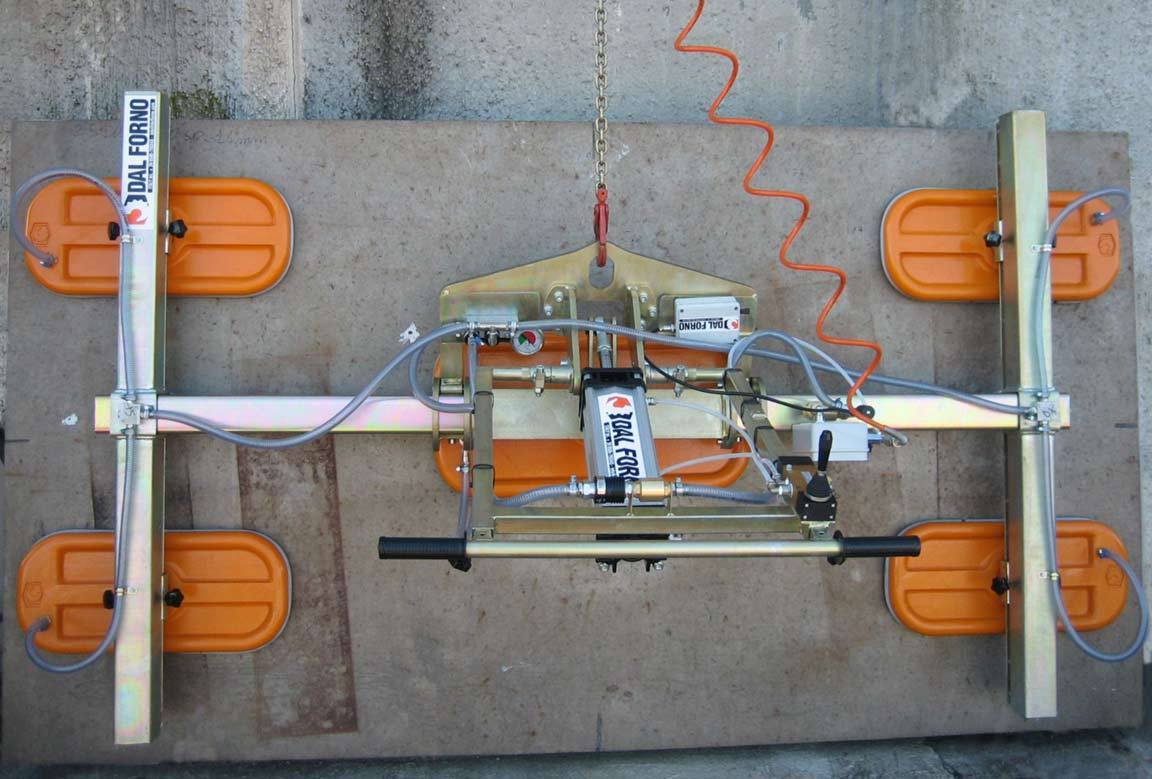

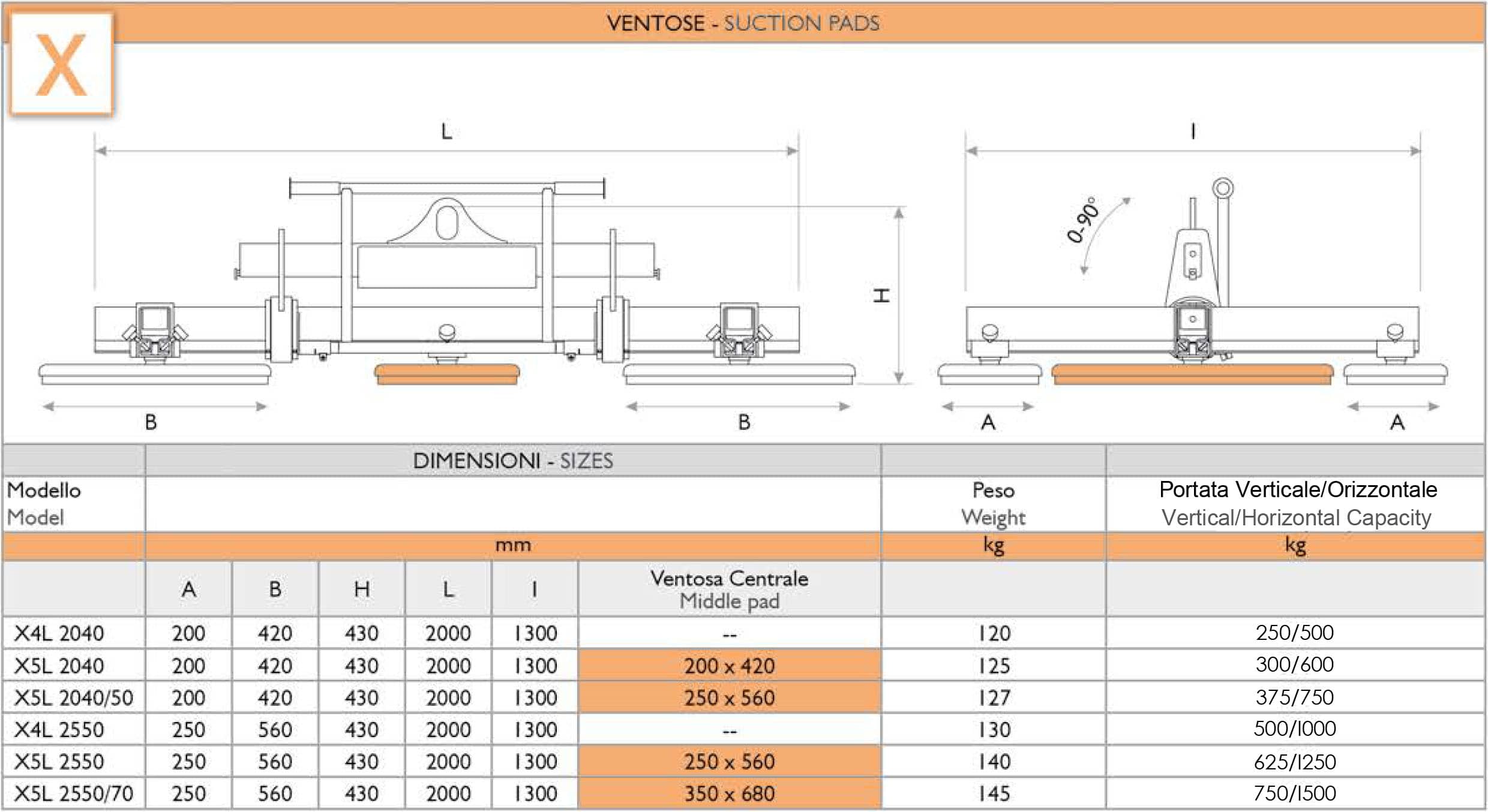

Ten pad vacuum lifter

Capacity: 500 to 1500 kg

Suitable for lifting solid material, not porous, having flat surface: cut-to-size panels, tiles, strips, stairs, small slabs, metal plates, window’s glasses.

Fast and simple handling unit, compact and sturdy constructed, suitable for continuous and heavy-duty use. Ideal under the hook lifting device, perfect complement to lifting equipment.

Equipped with vacuum reservoir, built-on safety devices with acoustic and luminous alarm systems, vacuum gauge.

A big step ahead is our distinctive rubber sealing, flexible, resistant and long-lasting, that allows gripping of any material finishing (raw, polished, honed, flamed, bush-hammered, sandblasted, etc.)

Advantages

Features:

- manufactured with light alloy materials and galvanized steel, aluminium casting pad – long-life and rustproof;

- fast and easy replacement of the rubber sealing ring;

- can be tilted 0° to 90°, to lift and lay down materials both horizontally that vertically (upright);

- pivoting axis close to the pad to facilitate the vertical positioning;

- adjustable inclination of the manoeuvring handle;

- detachable and rechargeable vacuum leakage alarm with buzzer and warning lights activated by a vacuum switch, apart battery charger;

- one-direction valves to allow vacuum keeping also in case of pipe cuts/vacuum loss;

- ON/OFF sliding valve with locking device against accidental releasing;

- in compliance with the CE Machine Directive to conform the EU standards for CE marking.

Feeding options:

The vacuum is generated by an electric pump or by means of a compressed air vacuum generator (Venturi pipe). The unit usually consists of: electric vacuum pump + connecting pipe + vacuum suction pad. The vacuum pump is to be placed nearby the working place. For special application can be supplied pumps with single-phase, DC electric motors (to be installed on fork lift and hydraulic crane), internal combustion ones.