CMS Kreator

Large Format 3D Printer with Integrated Milling

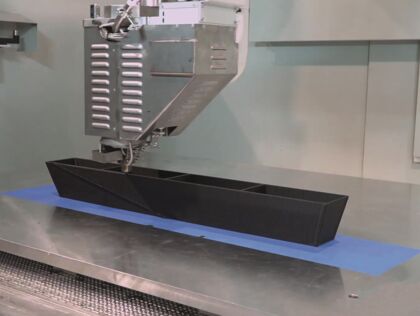

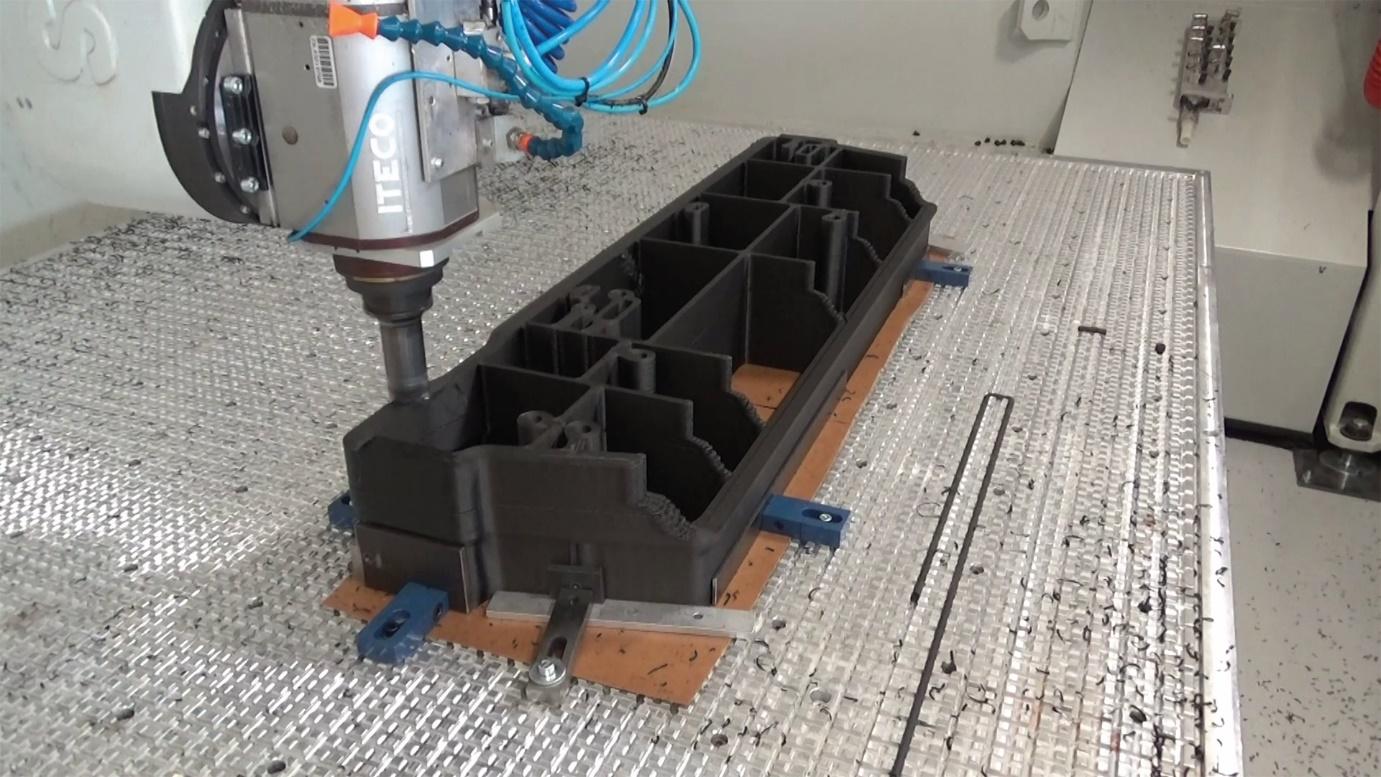

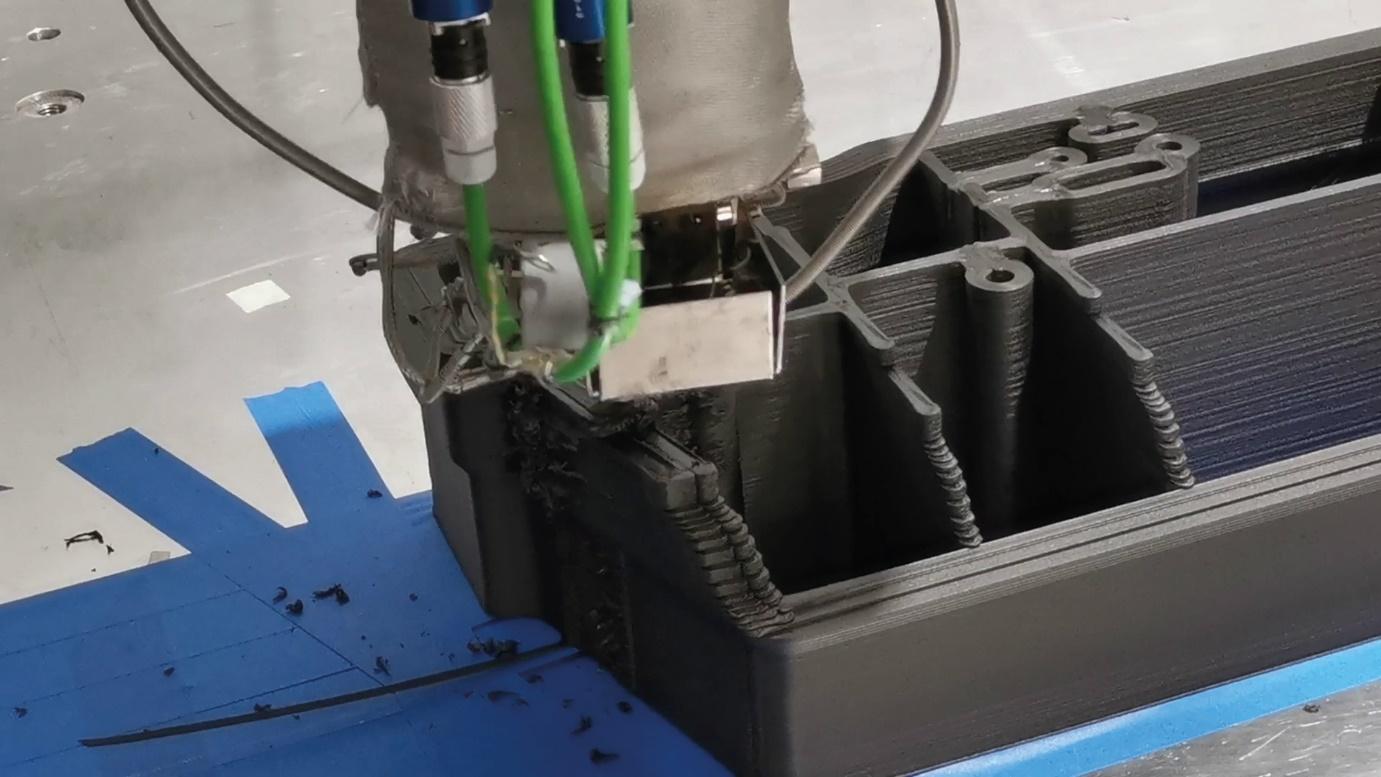

The CMS Kreator is a next-generation large format 3D printer that combines additive manufacturing with precision 5-axis milling — all in one integrated system. Designed for advanced material processing, Kreator enables fast prototyping and functional part production using thermoplastics and composite materials, followed by CNC finishing for high-performance tolerances.

Ideal for industries where scale, speed, and accuracy matter — from aerospace and automotive to design and tooling — the CMS Kreator redefines what’s possible in large-scale 3D printing.

Key Features

- Hybrid Additive + Subtractive System

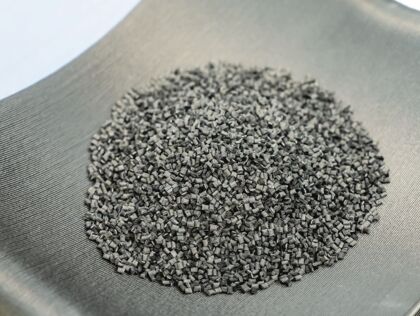

3D print complex parts using pellet-fed thermoplastics, then switch seamlessly to 5-axis milling for precision finishing — all in a single machine setup. - Pellet Extrusion Technology

Uses cost-effective thermoplastic pellets to reduce material costs and increase speed vs. filament-based systems. - Large Format Printing Envelope

Print parts up to 3m in length, making it ideal for full-scale prototypes, moulds, and structural components. - Automated Tool Switching

Move between additive and milling tools without manual intervention, improving efficiency and repeatability. - Multi-Material Capability

Compatible with high-performance materials including carbon-fibre-reinforced thermoplastics.

Applications

- Aerospace and automotive prototypes

- Moulds and tooling

- Architectural components

- Custom jigs and fixtures

- Advanced composite structures

Why Choose the CMS Kreator

- Combines speed of 3D printing with precision of CNC milling

- Reduces lead times and eliminates multiple production steps

- Handles large parts with industrial-grade repeatability

- Pellet-fed printing system lowers cost per part

- Built on CMS’s proven 5-axis milling platform